My new job is all about teaching youth about bicycles. So I get paid to take bike mechanic classes! Awesome.

A couple months ago I took a bike building class at a community shop. It was one of the most FRUSTRATING experiences I have ever had. Everything took forever and nothing was done correctly, and by the end I was just happy to roll out with a wobbly, untrued, bent spindle, ill fitting bicycle. The 25+ hours spent tearing apart and putting back together seems not to be in vain, having spent 6 hours adjusting a bottom bracket was actually just prepping me for actually understanding how to do it two months later.

The 9 hours spent yesterday at Blackstone Bicycles with Christopher Wallace was one of the best classes I've ever taken, everything he said made sense...it clicked...either he is the best teacher in the world (very possible) or all the frustrating hours spent before had propped me for beginning to understand bikes.

In order to spread bike love and mechanic exposure I'm going to list a few things I've recently learned. (I also work with a great mechanic who teaches 14 year olds...he is also really good at making me understand how a bike works or fixes.)

1. when you take things apart on your bike, don't actually take them all the way apart if you can help it. For example if you are changing brake pads, just loosen parts till you can pull what you need off, that way things don't get out of order or lost....sounds like we're morons, but it actually helps.

2. Righty tighty lefty loosy...FORGET THAT SHIT! When working with bolts, screws, etc it always drives me nuts trying to figure out which way I should turn. To remember pretend you have a screw in your hand and turn it to tighten. REMEMBER THE FEELING. Always remember the way it FEELS to tighten and then you can figure out anything (except for pedals...and a few other left threaded pieces). Using the feeling is good because you can work upside down and backwards and underwater etc.

(evidently Yellow Jersy is famous ...even in chicago... because they make all their mechanics work on bikes upsidedown...is that an urban bike legend?)

3. Toe your breaks so the front hits the rim before the back. The slant should not be big, you can get the right distance by putting a rubber band on the back end or a thin piece of cardboard at the bottom as you adjust to get the right slant.

towing will make your brakes more effective and stop squeaking. If your breaks are squeaking you should take a sponge with a little scrubby and some grease cutting soap and clean the rims, take a little sandpaper and run it over the brake pads to clean them and you should be alright.

4. Test your brakes after change or adjust them by squeezing the handle bar levers 10 times...as with derailliurs...you should try to break them while testing them...that way you'll be more sure it won't break while on the road.

5. There is a really genius easy way to make wheel hubs adjusted perfectly...it is based on the theory of 'finger tightening' I would be happy to teach anyone

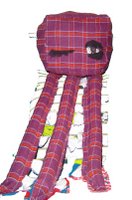

6. Despite everything I learn ...fixing brakes is always the most rewarding cuz it is easy and I use them all the time. The picture is of the brakes I took off this morning I should be shot for riding with them, they are completely smooth. My teacher told me a story about running over a biker and dragging him under his car for a while...the moral of the story=old fashioned metal is always best, his bumper was some old chrome so the biker could curl his fingers over the bumper and hang on as he was dragged under the car! For some reason mechanics always work in ways of telling you older metal was superior. The other interesting part of the story is that now the guy who told the story goes and steals bikes he sees without brakes and puts brakes on them...he figures this theft is a public service for stupid boys who don't know any better.

VOCAB...

--oil is oil (goes on chains etc) grease is 30% oil, the rest is dirt!

--brakes and deraillures are controlled by CABLES, not WIRES. don't call them wires, and remember they are kept in Cable HOUSING.

--A spindle spins an axel stays still. Inside your bottom bracket there is a spindle, connected to your cranks, rolling over bearings. I think inside your wheel hubs there is an axle, which the wheel spins around.